Designing the perfect LS Swap cooling system

Words And Photos: Cam Benty

No underhood headache is as frustrating as an overheating engine. Historically, big horsepower classic muscle cars required big radiators to keep the engine from percolating under pressure. Four core copper radiators were common, dressed with clutch fans and V-Belt drives.

Today, one of the most popular Resto Mod builds involves dropping some version of LS engine between the frame rails of a classic GM (or Ford) muscle car. And why not? These engines make big power, are compatible with a huge number of upgrades and can deliver a wide range of benefits both performance and comfort oriented.

For our ’71 Pontiac Firebird project, it was important to have a cooling system that was compatible with the 525 hp LS3 engine. Luckily the folks at Mattson’s Radiator, in Stanton, California, offer a complete drop-in system for LS swap applications. In addition to the obvious radiator fitment, they also offer everything needed to complete the install — electric fans, shroud, wiring harness and relay, air conditioning condenser, automatic transmission plate style cooler, and a lot more. If you stir in the fact that they have more than 50 years of experience, we felt they were a great place to fully understand everything involved.

As a new twist, the folks at SPAL, one of the greatest names in electric fans and fan systems today, have introduced a number of new break through products. At the head of the class are their “brushless” fans that reduce heat and provide increased cooling, lower amp draw, great durability and the ability to run at less than 100 percent speed to avoid the very common electric fan roar that is a signature sound of muscle cars (and OE) today.

As noted, Mattson Radiator has taken fan installations to an art form. Our installation was their first brushless fan system install in their long history, allowing them to integrate these new SPAL products into our LS-swap application. While these fans are more expensive than the standard, high quality non-brushless fans (also offered by SPAL), the brushless products offer a better than good solution for those looking for the ultimate fan efficiency.

SPAL Brushless Fans

As noted, key to the brushless fan design is reduced friction that comes from internal motor brushes. The removal of the brushes also delivers these key points:

LONGER LIFE: 2 to 3 times longer than brushed motors

NO MAINTENANCE: No carbon brushes to be changed

CLEANER: No dust residues

QUIETER: No electronic and frictional noise

NO ARCING (SPARK-FREE): Safe and less radio interference

MORE EFFICIENT = ENERGY SAVING: No brush friction, so power consumed is 28% less than brushed motors, based on the same output

SAVES: Energy, alternator life, battery life, belt life, maintenance and down time, smaller and lighter weight, highest torque/weight among all types of motors

VERY HIGH RELIABILITY: No commutator or brushes to wear out

VARIETY: Available in 12-, 16-, and 17-inch fan diameters

Space Issues

Prior to building a system, it is important to determine how large of a space you have to work with. A simple measurement from the back edge of the core support to the nearest engine component (with all accessories in place) will let you know just what type of radiator/cooling system you will be creating. In our case, we had a full 9.5 inches of space — a massive amount according to Mattson, allowing us to build the best possible cooling unit possible. That is not always the case. Mattson notes there are some times when a compromise needs to be made. Regardless, there are various systems that can be designed –including the use of their Sidewinder, which offsets the fan for extremely limited space demands.

Radiator Sizing

As noted earlier, to cool a big power engine in the past required a copper radiator with a large number of rows to achieve maximum cooling. That was then — this is now.

Today, JR Mattson (grandson of the legendary founder) recommends a two-core radiator with a multiple pass design, which sends the coolant through the radiator two, or even three, times. If your engine requires that the top inlet and the bottom outlet be on the same side, a two-pass radiator sends the coolant through the top half of the radiator where it makes a 180 degree turn and flows through the bottom of the radiator before exiting.

For high horsepower LS engine platforms with more than 600 hp, Mattson recommends a “three pass” radiator where the coolant spends more time in the radiator, making two turns within the radiator core. The key here is the fitment since a three-pass radiator mandates the inlet and outlet be on opposite sides of the radiator.

For high horsepower LS engine platforms with more than 600 hp, Mattson recommends a “three pass” radiator where the coolant spends more time in the radiator, making two turns within the radiator core. The key here is the fitment since a three-pass radiator mandates the inlet and outlet be on opposite sides of the radiator.

For all of their radiator applications, Mattson uses aluminum rather than cooper, the latter of which is heavier and holds heat longer, making the classic copper less beneficial. Mattson’s two-row aluminum radiator features large one-inch diameter tubes for smooth coolant flow. As opposed to four-core radiators that can actually block airflow, the two-row design is a free-flowing design and fits in the limited space generally found with LS-powered classic muscle cars.

And speaking of space, that is a huge determiner as to cooling system design. While the serpentine belt system used on most LS engines is fairly narrow compared with classic V-Belts and clutch fan arrangements, there are other things to consider when building up a system. Key determiners include the position of the engine’s air intake, radiator hose locations and sizes, and the needs of the A/C system. Most air intake systems involve some kind of S-bend that takes the intake from the center of the engine and drafts air from either the right or left side of the engine. Your intake may be different, but it is good to determine this now in case there is a cooling system conflict.

One of the more progressive features of the Mattson Radiator design is maximization of radiator width. Measuring 31 inches wide (much larger than most factory openings), Mattson systems are a big increase in cooling area over the OE units – and as such in cooling efficiency, not to mention heat transfer, is highly improved – to understate the obvious.

Fan Operation

For smaller than 24-inch wide radiator cores, Mattson recommends a single 16-inch diameter electric fan, and for the wider radiator applications, a pair of twin 12-inch diameter fans. In many cases, the twin fans deliver increased “center-of-the-radiator” clearance. Again, the space between the accessory belts and the radiator will determine the parts selection.

Mattson also offers a Sidewinder fan that allows the fan to be off center for special applications where the fans will not clear engine components. These fans are super powerful and draw a lot of air through the radiator. The application is the determiner here, and your radiator specialist can help you decide.

Decision time: Manual or automatic fan operation? If you want to manually control your cooling, you can install a switch inside you interior that will allow you to turn on the fans when you see your temp gauge reach a certain point. Most folks chose the automatic method. Some electric fans are tuned through the relay to come on at 25- to 50-percent power to slowly cool the radiator. This is common with the new SPAL brushless fans.

Mattson suggests not to do this with non-brushless fans and rather have the fans come on at 100 percent to get the cooling completed quickly and efficiently. When correct engine temp is reached, they will simply click off. You should place the temp sensor near the top inlet for the radiator, which is the hottest point on the cooling circuit. While this would seem obvious, some folks place it at the bottom outlet, which is completely wrong and a prescription for overheating.

Engine Temp

Theories regarding the most efficient peak engine operating temperatures abound. For some, an engine that runs more than 200 degrees is too hot. For others, 230 degrees is fine. It is really up to the owner and their engine builder to determine. As far as Mattson is concerned, neither is a problem.

“The LS engine is one of the most trouble free in terms of cooling,” states Mattson. “We can tune the cooling to the owner’s requirements through the selection of the thermostat. If they install a 165- or 180-degree thermostat, the engine will run under 200 degrees in most cases. If they install a 195-degree thermostat, the engine will run in the 200 to 230 degree range. Mattson’s suggestion is to make it run as cool as possible unless there are reasons suggested by the engine builder for the application.”

Installation

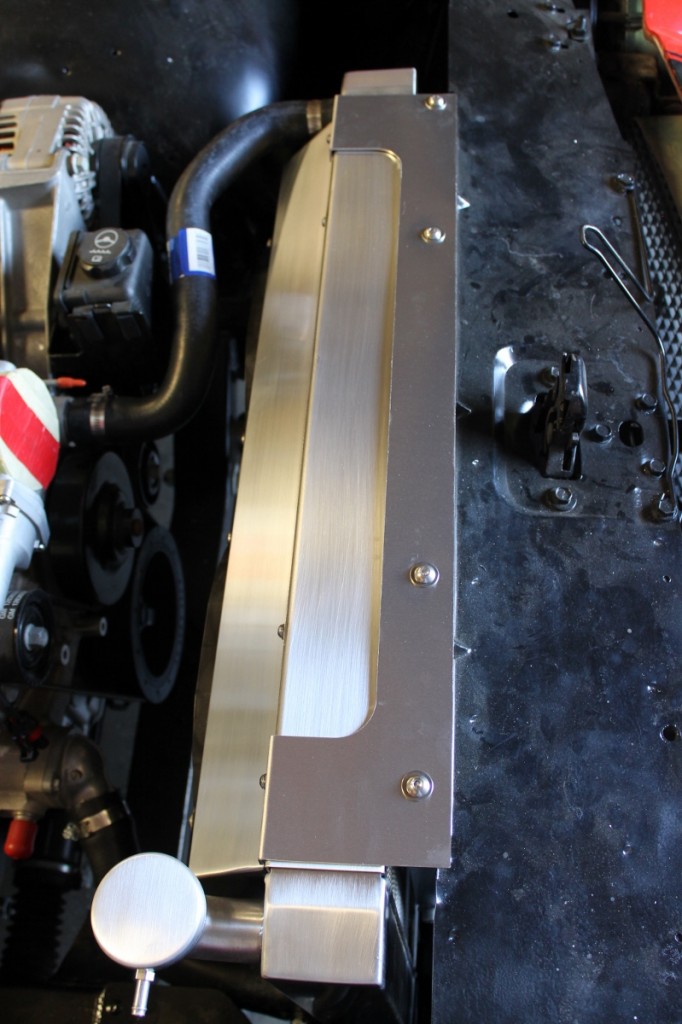

Mattson installed nutserts in the top of the core support and a custom panel that looks great and holds the radiator firmly in place. A pair of

brackets holds the bottom of the radiator in place using rubber isolators to avoid vibration damage.

For our ’71 Firebird — Second Gen F-Body, where the coolant outlet from the LS3 is in the center of the engine, we were able to create a three-pass radiator. This was great news – as noted earlier – since it allows coolant to pass through the radiator three times before exiting back into the engine. This is the maximum cooling efficiency possible.

With most radiators, there are rubber insulators that fit into the saddles at the bottom of the core support. For our radiator, custom brackets that slid over screws turned into the bottom of the support were used to keep the radiator in place. While that was a pretty smart design, it was the top radiator cover that was a real work of art — and a specialty of the Mattson Radiator fabricators.

While it is possible to use the factory style brackets on the top of the radiator, for best efficiency and that custom car look, Mattson constructed a cover that screws into nutserts placed in the top edge of the factory support. The top cover is made from aluminum and covers the entire core support and radiator system. With the twin brushless fans, specially constructed fan mount/shroud and “huge” radiator measuring 31 inches in width, a solid mount that keeps the unit in place with no chance of dislodging is critical.

Wrap up

As mentioned initially, designing a cooling system can be a challenge. Determined by the amount of space allotted and the amount of cooling system you can afford, there are plenty of options for a car owner. The new SPAL brushless fans are efficient and state-of-the-art, delivering a long list of benefits. With two core aluminum radiators, you have increased efficiency, lighter weight, and multiple pass designs that allow the coolant to flow more than one time through the radiator.

At no time in history have there been as many possible options for the car builder looking for problem-free cooling systems. Best of all, these systems work great with A/C, automatic transmissions, and all the possible power options you can dream up.

Spotting common radiator issues

Spotting common radiator issues

If you spot this kind of irregularity on your radiator, you’ve got a problem. This misshapen row of fins simply means your radiator has been damaged, most commonly by overheating and excess pressure.

What occurred at some point was an expansion of the tubing, which in turn, changes the look of the fins. The only fix — a new radiator core.

While the radiator will continue to hold coolant, its efficiency is greatly compromised as airflow is blocked as the fins spread out. It is recommended that if you see this condition, you determine why this has occurred to avoid such issues in the future and change out the radiator core.

Mattson Radiator cool for 59 years

When Jack Mattson started the radiator business, little did he know the legacy he had begun. Today, Mattson Radiator, combined with The Fan Man, are one of the go-to stops for folks looking to handle their cooling system issues. So for our LS swap project, it made sense to go to the experts to build the perfect system.

Jack Mattson Sr. is well known for not only his current line of products, but some legendary racecars. From Don Beebe’s record-setting fuel-altered to the Kurtis Kraft race cars of the ’50s, Mattson was the right guy for the job. Regardless of the race car or street bound machine, Mattson stresses that they are able to fix the cooling issue knowing that there isn’t much they haven’t see in the last 50 years.

As noted by JR Mattson, “while other radiator companies have some great products, they don’t have Jack Mattson Sr. That makes all the difference!”

Sources

Mattson Radiator

mattsonscustomradiator.com

SPAL Fans

spalusa.com