And the parade of great presenters at the AETC Conference continues.

And the parade of great presenters at the AETC Conference continues.

After lunch, Lee Carducci of Arrow Racing Engines was the first up. Arrow builds the all the racing engines for Dodge’s Viper racing program. We’re talking victories in the 24 Hours of LeMans (the GT2 class), the Rolex Daytona 24, the 24 Hours of Nurburgring, and the list goes on. We were blown away by how open Carducci was when going through his Viper racing engine program from air cleaner to the oil pan.

Engine Development

We’ve heard for years that the Viper V10 engine is just an LA series engine with a couple extra cylinders. That actually couldn’t be further from the truth. Carducci says that part of the engine development was handled by Lamborghini Engineering in–you guessed it–Italy.

We’ve heard for years that the Viper V10 engine is just an LA series engine with a couple extra cylinders. That actually couldn’t be further from the truth. Carducci says that part of the engine development was handled by Lamborghini Engineering in–you guessed it–Italy.

Rotating Assembly

The stock twisted forging crankshaft is used in all Arrow’s racing applications because Carducci says it can reliably handle 1,000 horsepower. The connecting rods are also quite strong, but they are made of powdered metal and the cracked cap design can be weakened after multiple rebuilds so Arrow worked with Lunati to develop a forged connecting rod. Pistons are from Mahle, and the goal is mainly to cut weight from the stock design, not necessarily to improve strength.

The stock twisted forging crankshaft is used in all Arrow’s racing applications because Carducci says it can reliably handle 1,000 horsepower. The connecting rods are also quite strong, but they are made of powdered metal and the cracked cap design can be weakened after multiple rebuilds so Arrow worked with Lunati to develop a forged connecting rod. Pistons are from Mahle, and the goal is mainly to cut weight from the stock design, not necessarily to improve strength.

Cylinder Heads

When machining cylinder heads, most companies locate everything off the combustion chambers. Arrow completely reshapes the stock combustion chambers on CNC machines. Since everything in the combustion chamber moves, Arrow locates their heads before cutting off the ports. Carducci says this saves time and machining operations.

When machining cylinder heads, most companies locate everything off the combustion chambers. Arrow completely reshapes the stock combustion chambers on CNC machines. Since everything in the combustion chamber moves, Arrow locates their heads before cutting off the ports. Carducci says this saves time and machining operations.

The intake port Arrow uses has a large “fin” to help control air flow. At first the fin looks like a major obstruction and many “experts” have tried to take it out thinking they could improve air flow. But even though it looks like an obstruction, the fin helps imrove the quality of airflow into the combustion chamber which results in real power.

The intake port Arrow uses has a large “fin” to help control air flow. At first the fin looks like a major obstruction and many “experts” have tried to take it out thinking they could improve air flow. But even though it looks like an obstruction, the fin helps imrove the quality of airflow into the combustion chamber which results in real power.

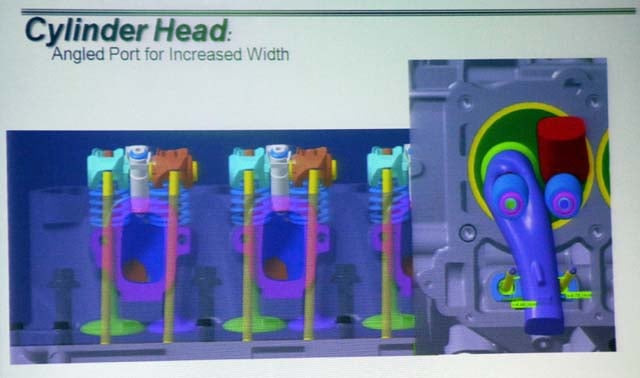

Angled Ports

Pushrods typically create “pinch points” in order to make room for the pushrods. Instead of compromising the port in order to get the pushrods past, Arrow actually “leans” the ports over. It looks unusual, and you may think that airflow could be improved by straightening the ports up, but Carducci says that by leaning the ports it increases the overall width and helps move more air.

Pushrods typically create “pinch points” in order to make room for the pushrods. Instead of compromising the port in order to get the pushrods past, Arrow actually “leans” the ports over. It looks unusual, and you may think that airflow could be improved by straightening the ports up, but Carducci says that by leaning the ports it increases the overall width and helps move more air.

Variable Valve Timing

The Viper achieves variable valve timing by using a camshaft within a camshaft. That means there is a hollow shaft with the exhaust lobes attached. Within it is another shaft with the intake lobes pinned to it. By using a phaser the Viper engine can move the intake centerline relative to the exhaust to help make a very broad, very flat torque curve. Carducci says movement is around 80 degrees.

The Viper achieves variable valve timing by using a camshaft within a camshaft. That means there is a hollow shaft with the exhaust lobes attached. Within it is another shaft with the intake lobes pinned to it. By using a phaser the Viper engine can move the intake centerline relative to the exhaust to help make a very broad, very flat torque curve. Carducci says movement is around 80 degrees.

Development for this system is very expensive–believe it or not, Carducci says prototypes cost around $10,000. So Arrow developed a fixed camshaft system with the help of Comp Cams that’s used with several different teams. It is more traditional old-school, but it makes racing more affordable for the teams and allows quick cam changes.

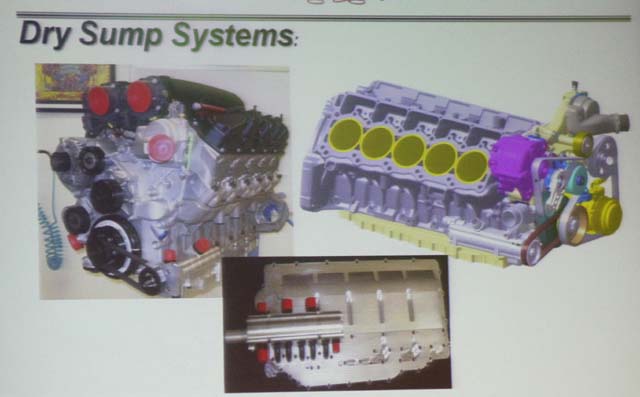

Custom Dry Sump

We just included this one because we thought it will someday be a cool trivia question. Arrow has traditional dry sump setups with the pump located on both the left and right side. But notice the dry sump pan and pump in the bottom photo that Arrow worked with Dailey Engineering to develop. The pump is actually below the pan, which is quite unusual. The reason is this is for customers in Saudi Arabia and they–quite understandably–are hesitant to give up their air conditioning. So to find a place to put the pump without interfering with the air conditioning pulleys, Arrow located the pump below the oil pan.

We just included this one because we thought it will someday be a cool trivia question. Arrow has traditional dry sump setups with the pump located on both the left and right side. But notice the dry sump pan and pump in the bottom photo that Arrow worked with Dailey Engineering to develop. The pump is actually below the pan, which is quite unusual. The reason is this is for customers in Saudi Arabia and they–quite understandably–are hesitant to give up their air conditioning. So to find a place to put the pump without interfering with the air conditioning pulleys, Arrow located the pump below the oil pan.