For the past few years, at the Spring Festival of LX, I’ve made a point of checking out Matt Leischer’s 2006 SRT8 Chrysler 300C. Typically showing every bit of the 200,000+ miles the car has on the odometer, Leischer’s 300C isn’t your typical Gen III Hemi build, and that’s precisely why I go out of my way to see Matt’s latest handiwork.

What’s special about Matt’s build isn’t the amount of power it makes on the dyno, or the fact that a Chrysler 300C seems like an unlikely candidate for an homage to Mad Max. What really sets this build apart from the crowd is that it exists largely through sheer strength of will.

Project A-Bom in more-or-less its latest configuration. Matt has already started wrenching on the car again since we caught up with him at Spring Fest 13 just a few weeks ago.

In an era where off-the-shelf solutions are the norm, Matt chose to take the path less never traveled, simply engineering his own solutions to issues that have come up along the way rather than reconfiguring his build to suit aftermarket parts availability. In that regard, I think Project A-Bom embodies the true essence of hot rodding.

“I always wanted to do something that would have a big visual impact,” Matt told me. “Before this build, I had worked on projects more along the lines of subtle, sleeper-type stuff, so I wanted to do something kind of bold. The whole Mad Max thing came out of just being a fan of the look of the cars in The Road Warrior, and I thought it would be neat to build something that just had a different scope than your typical modern show car. I wanted to get away from the standard bolt-on parts that everyone was using.”

Now dubbed the A-Bom, over the years Matt’s build has been through a few distinct iterations, including a phase that just recently came to fruition.

And like any ambitious DIY engineer, Matt already has his sights set on the next chapter for the 300C. But we’ll get to that later. In the meantime, let’s bring you up to speed on the history of this bitchin’ modern Mopar.

Phase I

“I picked up the car in 2007 as a used ’06 model, and of course I did a handful of normal bolt-on stuff,” Matt explained.

“One day I was looking at one of Chrysler’s press photos for the 300C, and I decided to photoshop a blown-injected type setup on it, thinking about how cool that would be. After a while of looking at it, I started thinking, ‘Wait – I could actually do that.’ The end goal actually became a moving target as the build got more involved. I had a general plan, but as I came across issues I would basically just assess the best way to solve them – whether that was climbing the mountain or going around it – and continue on from there.”

The end goal actually became a moving target as the build got more involved. I had a general plan, but as I came across issues I would basically just assess the best way to solve them – whether that was climbing the mountain or going around it – and continue on from there.

Matt says that he would sometimes come to what he described as a “point of resistance”, which basically translates to an absence of existing parts to continue the build as he’d intended, and he would have to determine whether to go the safe route, or simply fabricate the parts himself. “It often just came down to how much time and effort I wanted to invest in that particular piece,” he told me. “And that would kind of guide the path of the build as I went, which was kind of exciting in and of itself.”

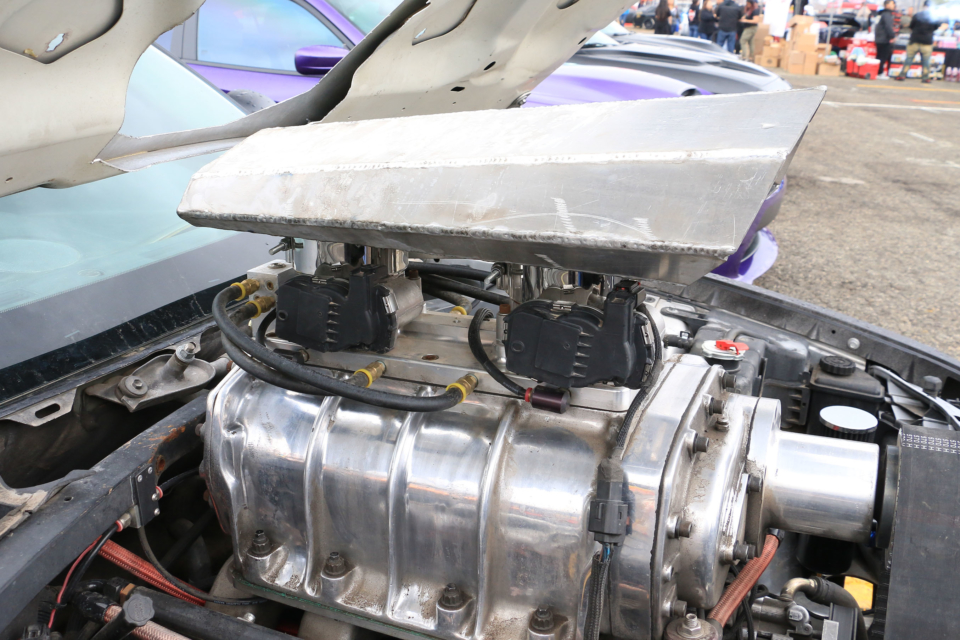

Leischer sourced a rebuilt 6-71 GMC blower from eBay that had previously been used on a 327-powered T-bucket. Finding the supercharger was the easy part though – making it work within the confines of the 300C engine bay would prove to be the real challenge. The Scott Fuel Injection scoop on the right helps complete the Mad Max look.

The first big phase of the build got underway in earnest back in 2012. Matt says that a lot of the initial work was simply brainstorming ideas. “I would see a piece of someone’s custom work and think, ‘Oh, there’s an idea of how I could make a bracket or a pulley that would work for this blower scenario.’ Eventually, I got enough pieces of the puzzle together that I convinced myself that I could make it happen. Then Roadkill did the Draguar build and I was like – ‘OK, I’ve got to make this happen.’ If they can build that thing in a parking lot, I can pull this off.”

One of the biggest initial obstacles was determining how to get this kind of blower configuration to play nice with the rest of the car’s electronics. “The original setup used a pair of OEM throttle bodies on a custom fabricated housing that were running an electronic controller from Ozmo Engineering out of Australia,” he says.

“I just kept having drivability issues with the controller running both the throttle bodies in parallel. So I wanted to find a solution to running them progressively, in kind of a primary/secondary setup. There just wasn’t an electronic solution that was going to work, so I started in designing a mechanical secondary. By then, the Hellcat throttle bodies were available and surprisingly accessible – the earlier ones were kind of sealed shut and when you took them apart there was no return. The Hellcat ones I found that I could take the motor structure out of one and create a mechanical linkage. So I went to town doing digital drawings and CAD work to put the pieces together and figure out the armature linkage that was going to give me the correct ratios for opening the secondary throttle body based on throttle input, and make sure that they both meet at 100% throttle at the same time.”

Sky-high intake air temperatures and largely stock internals didn’t do the blown setup many favors early on, but the 300C still made more than enough grunt to roast the tires in spectacular fashion.

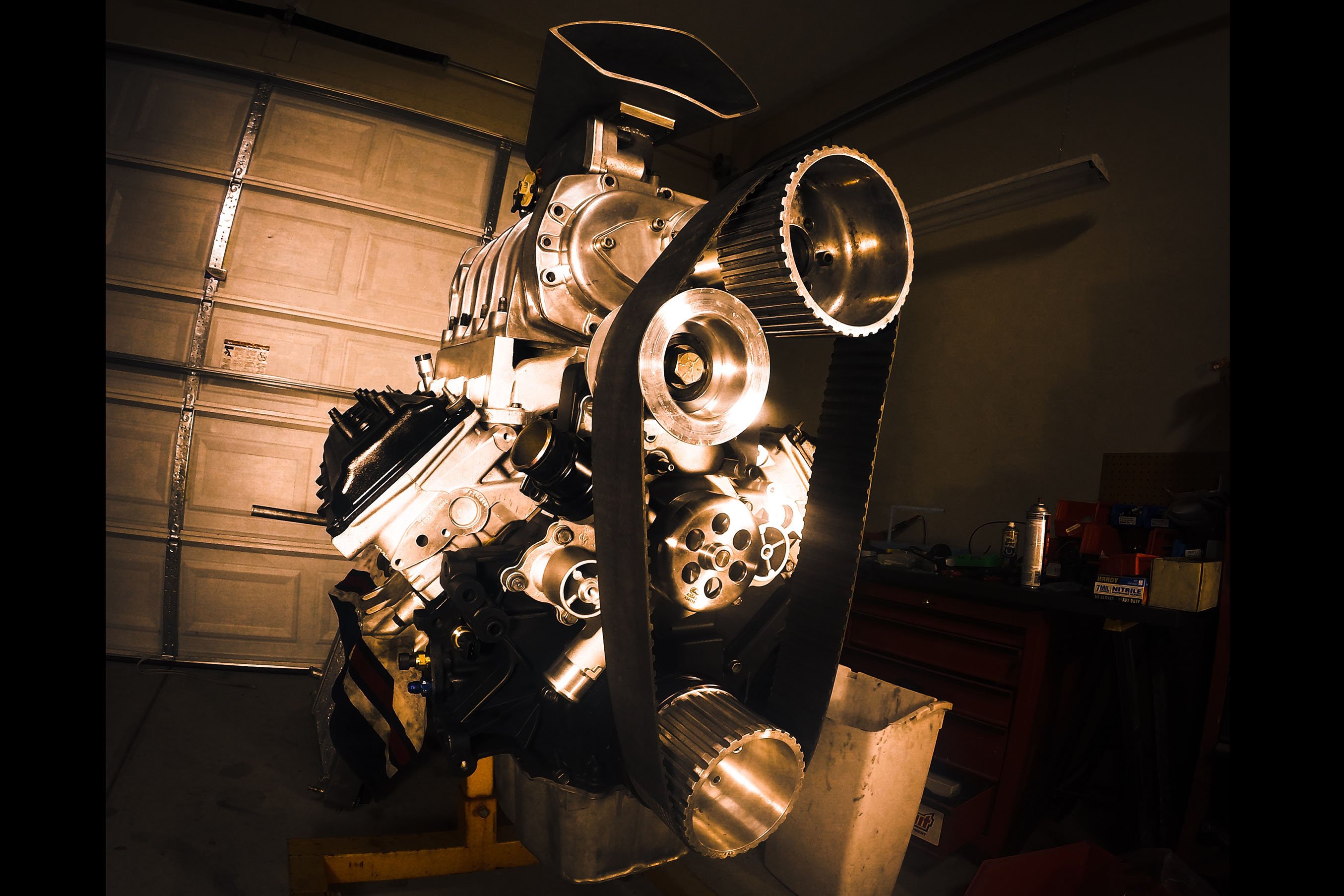

The initial combination could perhaps be best described as pragmatic – a 6-71 blower running at about 7lbs of boost on a near-stock, high-mile 6.1-liter Gen III Hemi with an Inertia Motorsports camshaft, which dyno’d right around 500 horsepower to the rear wheels in 2015.

The Hemi Goes Heavy

Matt was well aware that with the boost now involved, that motor and its stock bottom end probably weren’t long for this world. “In the summer of 2015 it dropped an exhaust valve at wide-open throttle when I was passing a semi on a two-lane highway, and a blaze of glory let loose,” he joked. “It was a known eventuality that the motor was going to need to be rebuilt or replaced. I’d expected it to fall apart long before that – the only surprise was the way it went out. I figured it would be a piston coming apart or a rod kicking out of it, not an exhaust valve.”

Matt knew going into the build that the aging 6.1 was going to live a short life once he added boost to the equation, so a parts failure didn't come as a big surprise. Dropping a valve was unexpected though. Fortunately his machine shop was able to mend the damage by simply re-sleeving and over-boring the block. This time around, the Hemi got the stout bottom end it always deserved.

But the death of the 6.1 put Matt at a bit of an impasse. “The question was whether or not to rebuild the 6.1 or move to a 5.7-liter Hemi,” he told me. “The idea behind the 5.7 was to get the longer stroke and smaller bore so I could keep a nice, thick amount of block around the cylinder for strength. But I already had the 6.1, and to my surprise, it was determined to be salvageable by my machinist. It was scored up pretty bad because it basically disintegrated the #1 piston when that valve dropped in there, but it didn’t break anything or crack the block – it just needed to be sleeved and over-bored a bit.”

Now displacing 6.5 liters, the Gen III Hemi got the internals needed to properly handle the boost – a forged K1 crankshaft, steel H-beam rods from Molnar, and a set of custom-spec pistons from Wiseco. “With the pistons, I knew I was going to have to do something special,” he said. “I contacted Wiseco and they were super into the build. They were able to put together some neat ideas to try out on this, and it turned into a really nice piston design.” The Hemi also received a custom Bullet camshaft and a different set of 6.1 Hemi heads, the latter of which were installed after being hand-ported and polished by Leischer himself.

A-Bom at Spring Fest 12 last year.

Although still lacking an intercooler, the new hardware woke the Hemi up substantially, which was then dishing out 650-700 rwhp by Matt’s estimate. The build stayed largely the same throughout the rest of the year, but in March of 2016, fate would step in to test Leischer’s resolve once again.

The Unexpected Rebuild

“I was on my way to pick up a pizza on a two-lane road and the guy behind me fell asleep at the wheel and woke up at the last minute,” Matt recalls. “He tried to avoid me by passing me on the left, but he ended up hitting oncoming traffic in the opposite lane. At that point he ricocheted off the other vehicle and into my left rear quarter, basically kicking the rear end out from under me like a police PIT maneuver. That sent me into a telephone pole square in the middle of the car.”

The telephone pole wasn’t particularly kind to the Chrysler, but given the circumstances, Matt says he got very lucky.

From the initial assessment, the damage report didn’t look pretty. “It destroyed almost all of all the front bodywork – bumper, grille, front fascia, hood, etc – along with the damage to the rear driver’s side quarter,” Leischer recalled. “And that was just the stuff I could immediately see at the time.”

For a while, Leischer was left wondering if he would have to scrap the car entirely and start over on something else. “Luckily it didn’t do any frame damage,” he explained. “For what happened, it went about as good as you could hope for.”

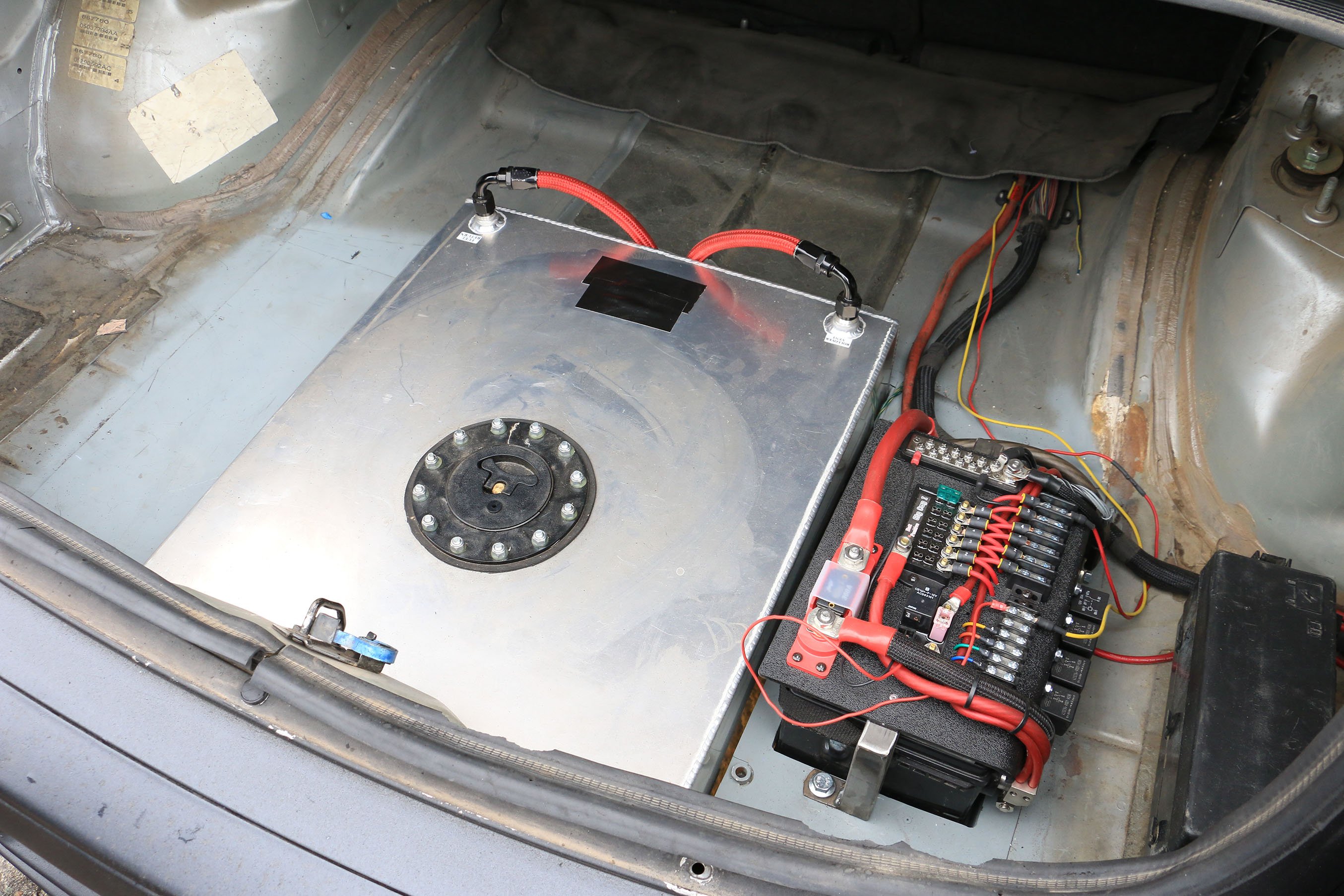

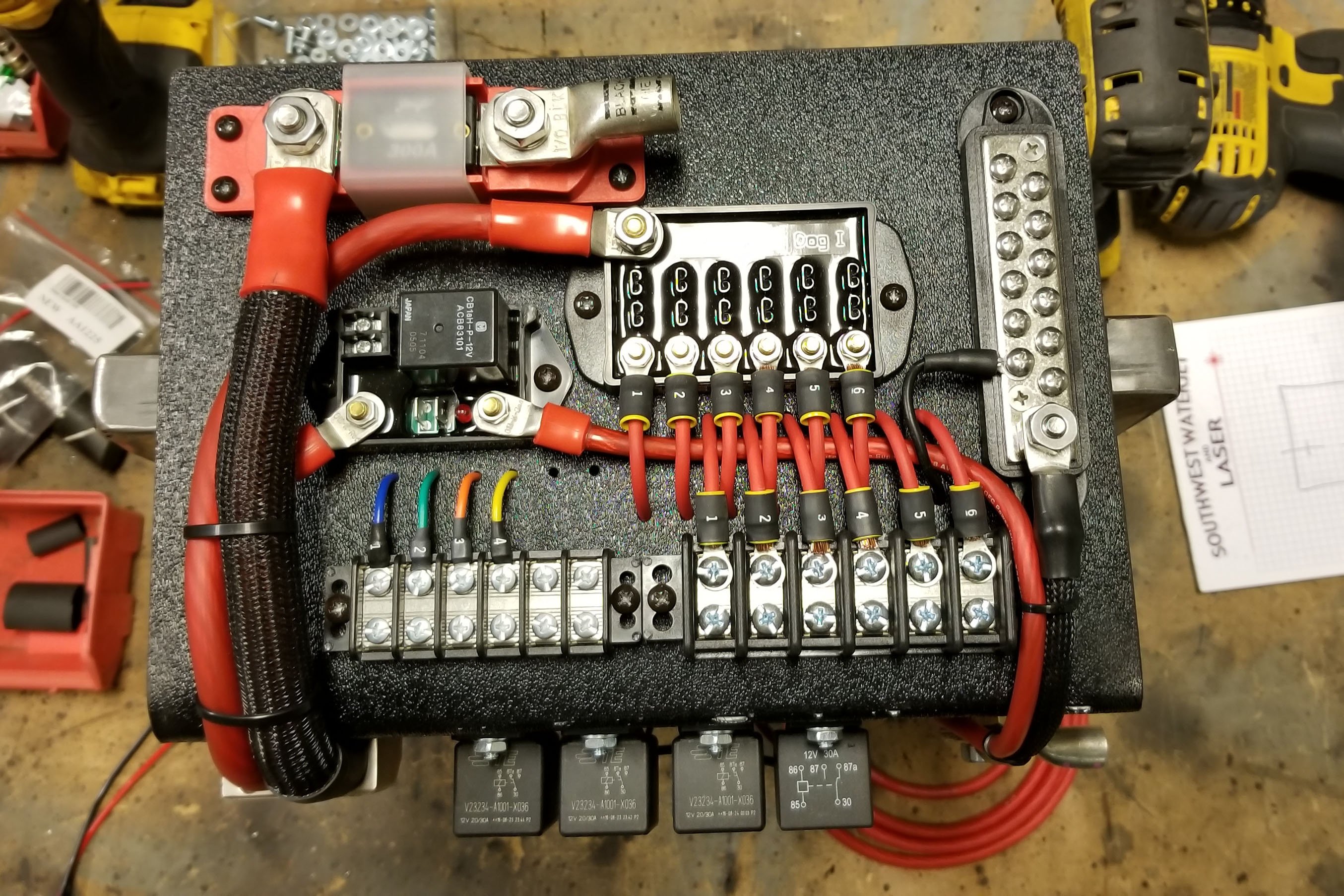

In the end, it proved to be just another stage in the build. “I just looked at it like, ‘What are we going to change this time around now that we’re going to have to do this work anyway?'” he said. “While I had it apart, I cut out the trunk floor so I could move to a fuel cell and upgrade to an Aeromotive fuel system. The original tank was already suffering from a recall they’d had on those for the check valve, so it was a great excuse to do it.”

Due to the body damage, the car’s aesthetic inevitably had to be changed up a bit as well. “As to be expected, the front fascia and those other parts were replaced, and I put an OEM grille on it for simplicity at that point – I didn’t really have time to do anything different before Spring Fest,” Leischer explained. “I was able to get the Gatling gun-style fog lights back in there, and this time I put a spacer in to extend them out a little further. Then I re-sprayed the car with a Plasti Dip foundation, along with a clear Plasti Dip top coat, which serves as sort of a vessel for a powder pigment. It gave it this off-black pearlescent shade that’s very muted, but definitely sets itself apart from your standard flat black look.”

Matt says he was a bit pressed for time leading up to this year's Spring Fest, so the setup he had hoped to bring to the show wasn't quite ready for prime time. While I have to admit that I missed the road-worn aesthetic of the car from last year, I was really just happy to see the 300C alive and kicking again.

After that, Matt removed the Plasti Dip from the 22-inch wheels to reveal the bare chrome, and that’s essentially how it arrived at this year’s Spring Fest. “Since it’s been re-sprayed, I kind of figured it didn’t have quite the same disheveled look from before, so I thought I’d pretty it up a little,” he added.

The Road Ahead

Perhaps unsurprisingly, Matt’s already got a laundry list of stuff that he’s preparing to do to the car since we saw it earlier this month. “The new intercooler is going to get put on soon,” he explained. “The engine is built for 1000+ horsepower with the proper amount of boost and airflow, so having the intercooler will definitely give me the air temperature necessary to at least make some safe power. But I think the supercharger airflow is going to be the limiting factor at that point, so going to either a more efficient 6-71 or stepping up to an 8-71 will probably determine where the power is at that point.”

I’ve been getting positive feedback from all over the place. You know a lot of folks are either Mopar guys or F-Body guys or whatever. This just kind of gets past all that for whatever reason, and I love that about it – I never wanted to build something to just be in one “class.” If it’s a cool car, I’m all for it.

He’s got no shortage of plans on the aesthetic side of things, too. “I have some ideas for a custom metal grille I’d like to make, and I’ve started work on a splitter for the front end made out of aluminum diamond plate. This thing is basically a big, rolling R&D project.”

The intercooler setup is a cool piece in and of itself, providing the blower with both cooler air and a higher profile. RIP, right-hand turns.

In the meantime, however, Matt’s 300C has proven to be a project that can cross borders. “I’ve been getting positive feedback from all over the place. You know a lot of folks are either Mopar guys or F-Body guys or whatever. This just kind of gets past all that for whatever reason, and I love that about it – I never wanted to build something to just be in one “class.” If it’s a cool car, I’m all for it.”

It’s a sentiment I certainly share with Matt, and it’s one of the many reasons that this 300C is worthy of all the attention it has received over the years. Competition is fun, but when a build can transcend the us-versus-them dynamic that’s so prevalent in the hobby, that’s really saying something. I can’t wait to see what’s next for Project A-Bom.