Carbon fiber driveshafts are state of the art for racing forms of all types, and high performance street applications.

Carbon Fiber driveshafts rewrite the book on driveline performance

In the world of high-performance driveshafts, there are plenty of opinions regarding the perfect part for the job. In the past, an assortment of materials, from steel to aluminum, have been used for driveshaft construction. As with most things performance, the lighter the better, as long as strength and fitment are not compromised.

Along with the material selection, the diameter of the driveshaft has been of critical importance in determining strength — exponentially affected by the overall length of the shaft. As Jeff Smith’s accompanying story for critical speed covers in detail, there are very serious dynamics at work here. Not taking the time to understand this information is as ignorant of the facts as standing in a puddle of water when you plug in your toaster, or telling Mike Tyson his tattoo is misspelled. In a word — don’t do it!

As you should know after reading the title of this article, carbon fiber has entered into the discussion of driveline materials. That amazing material used for body panels and chassis components has trickled its way down to the performance driveshaft arena. Many racecars currently use this super light, super strong material with huge success. News Bulletin: Now you can have it for your street performance car.

How it’s Made

This magnificent piece of machinery allows QA1 to control the manufacturing processes for creating a carbon fiber driveshaft. Once the driveshaft has been designed and data input, the machine takes it from there.

The folks at QA1 offered to show us just what it takes to build a carbon fiber driveshaft. After all, carbon fiber requires completely different construction methods than metallic driveshafts. All QA1 driveshafts are built in their Lakeville, Minnesota, facility to deliver the exact torsional stiffness desired.

Having significant expertise with carbon fiber materials, QA1 found with driveshafts that it was imperative to have control over the entire filament winding process, thus the need for full in-house capabilities. Not only do they measure the overall length with great precision, they can also determine wall thickness and winding patterns. Having this capacity enables them to have carbon fiber driveshafts that fit the usage — offroad, on track or street performance — each one with unique build characteristics.

Once the full picture of the desired driveshaft sizing is determined, it is loaded in the fully computer-operated driveshaft building machinery. As the carbon fiber windings are wrapped around the carbon fiber core, 3M Matrix resin is applied. QA1 offers driveshafts in thickness from 2.7 to 3.7 inches.

As the carbon fiver strands are wrapped carefully to form the shaft, 3M resin is applied to make it strong. Today, QA1 makes driveshafts in diameters of 2.7, 3.2 and 3.7 inches.

Why Carbon?

As opposed to metal driveshafts, which are cut and balanced to fit, the carbon fiber driveshaft is a built-

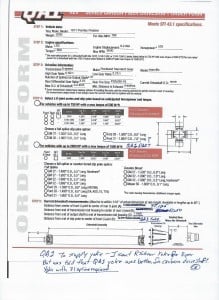

Of critical importance is making sure the driveshaft specs are correctly measured. On this order form, it is critical to get not only the length of the shaft right, but all ancillary parts, including the yoke and u-joints. To modify the old adage, measure three times, write it down once.

to-fit unit — no cutting involved. The carbon fiber driveshaft adheres to the yokes that hold the u-joints with an 11-step bonding procedure that ensures they won’t come loose.

As with anyone who has seen a metal driveshaft and u-joint failure, the damage to the surrounding flooring of the vehicle can be catastrophic. With carbon fiber, in the event of failure, the driveshaft shreds, causing no collateral damage, which means easier repairs and quick return to vehicle service.

A carbon fiber driveshaft carries tighter tolerances than metal shaft due to the way it is formed. For that reason, there is less balancing involved to prepare for usage. With CNC-machined yokes, proper axial alignment is achieved to reduce vibration — the main cause of driveshaft and u-joint failure.

If there is any question about carbon fiber driveshaft quality, QA1’s REV series driveshafts are certified to SFI 43.1 standards, which are the highest racing standards required for competition.

Final touches

Carbon fiber driveshafts are built to fit – no cutting involved. The carbon fiber driveshaft ends adhere to the yokes that hold the U-joint with an 11-step bonding procedure that ensures they won’t come lose.

Once the tube yokes are inserted into the entire driveshaft component, it is tested for ultimate strength before delivery to the customer. The tests involve torsional spring rate and fatigue life through a barrage of NVH checks. In addition, the driveshaft is then high-speed balanced to avoid driveline vibrations and ensure quiet operation.

For our application, the 3.7-inch diameter shaft was created to handle the 525 lb-ft of torque output by the LS3 engine. The larger shaft gives us insurance should we decided to go with a power adder program that would put us in a higher power bracket — but no where near the limit to this strong shaft.

The attached diagram shows the driveshaft built for our 1971 Pontiac Firebird that features the Rockland Standard Gear six-speed, LS3 engine, and Heidts Independent rear suspension. We bring up these points because, as you can see, this is a completely custom driveline requiring a driveshaft that is both sturdy and fits these dynamics. With a 525-hp engine, these driveshafts are barely challenged — able to handle up to 2,000 hp and the most grueling race environments.

Our biggest challenge was self-inflicted. Due to the Heidts IRS suspension and an exhaust featuring 3-inch diameter tubing, there was little room to operate. To slide the QA1 driveshaft in place took some creative manipulation, but the shaft did manage to fit in the designed location. Of course, tightening the u-joint straps took at least twice the time as if we had clear access.

For anyone interested in a carbon fiber driveshaft, the personal experience with the process, including installation, was excellent. Our driveshaft fit perfectly, and for the limited time we have now used the shaft, we have encountered no issues. We could not be more pleased.

Source: QA1, QA1.com