By Jeff Smith

Big displacement engines like this 520ci Jon Kaase Boss 9 engine make building a car that accelerates briskly very easy. Even in a heavy car with an automatic will be a thrill with an engine that can make over 900 horsepower with an astonishing 700 lb-ft of torque way down in the rpm curve.

In the performance game, the talk is all about horsepower. It’s splashed across magazine covers and horsepower numbers are prominently displayed especially now when the numbers are over 1,000. It seems that we are forever being indoctrinated into believing the horsepower is the great solution. And most of the time, that’s correct. But not always. If you are building a Bonneville car or a top speed race car, then peak horsepower is a very powerful thing. But for a drag race car or even a mild street car – a big peak horsepower number is not always the best solution if you’re trying to build a car that’s quick. When we say quick, let’s define the term. In the early days of drag racing, the winner was always the guy who got there first, but they identified the strength of the run based on trap speed. In top speed racing, you are given a long run like five to seven miles to achieve terminal velocity. But in modern drag racing – you only have a quarter and sometimes only an 1/8-mile – 660 feet – to take the stripe. A quick car is one that will get there in the shortest amount of time – and that’s what we’ll dissect in this story.

We might want to define the terms we’re working with here just so there’s no confusion. Internal combustion engines are rated using two different types of power – torque and horsepower. These ratings are directly related yet different. Basically, torque is a measurement of a twisting motion – like that generated by the output of an engine’s crankshaft. This torque is expressed in pound-feet (lb-ft) so that one lb-ft is the force required to twist a shaft with one pound of effort over a one-foot radius. What this measurement doesn’t describe is the amount of time required to perform this effort. Once we introduce time into the equation, then we can define that amount of effort (torque) over a given amount of time – which in an internal combustion engine’s case is expressed in revolutions per minute (rpm). This amount of work was given the term horsepower by James Watt back in the 1700’s to compare the amount of work his improved steam engine could produce compared to the amount of work performed by a typical draft horse, which was something his customers were intimately related.

The equation that Watt created has been simplified to: Torque x RPM / 5,252 = HP

To give this an example, let’s say our engine makes 300 lb-ft of torque. At 3,000 rpm this means the engine is only making 171 horsepower (300 x 3,000 / 5,252 = 171). However, if we add performance parts to our engine and spin it a little faster, it is capable of making that same 300 lb-ft of torque at 6,000 rpm. By doubling the rpm at which the engine can make power – we now have a more powerful engine making 342 or twice the horsepower. The reason for this doubling of horsepower is that the engine is making the same torque in exactly half the time of the first engine – 6,000 instead of 3,000 rpm. Given the choice, most hot rodders would choose the more powerful engine. But in the performance world, things get a bit more complicated.

The reason that large displacement engines are so popular with performance enthusiasts is that as displacement increases, so does the ability for the engine to make more torque at lower engine speeds. Which is why hot rodders love big engines. A typical performance V8 engine can make 1.2 to 1.25 lb-ft of torque per cubic inch of displacement. For a 300ci engine, 300 x 1.25 = 375 lb-ft of torque, which for a pump gas street engine is a decent torque number. But now let’s apply that same 1.25 lb-ft per cubic inch plan to a 520ci big-block Ford and suddenly the numbers become a bit more Kong-like: 520 x 1.25 = 650 lb-ft of torque. This is no secret and also just puts numbers to what hot rodders have known for years – big engines make big torque.

Torque is what really moves the car, but it gets lost in the bench racing sessions when everybody only wants to talk about horsepower. But let’s go back a bit and look at engines like the Buick and Pontiac 455 ci engines. They made great torque but because of their limited cylinder head size and greater internal friction from long strokes, these larger displacement engines were not as efficient in terms of horsepower per cubic inch. There are exceptions of course, like 500ci NHRA Pro Stock engines that spin to 10,000-plus rpm and make upwards of 1,400 horsepower. At 2.8 hp/ci, these normally aspirated monsters are exceptional, but also somewhat peaky, engines. What this means is that race engines like these tend to have relatively narrow power bands where all the power is concentrated in a range of 1,000 to 1,200 rpm. We’ll define this power band as the rpm spread between peak torque and peak horsepower. A common problem with race engines is that escalating horsepower and rpm are accompanied by an increasingly narrow rpm range where the engine really makes its power.

This also occurs with street engines. Making power with any internal combustion engine is a compromise between torque and horsepower. The search for additional horsepower for a normally aspirated engine follows the path of the horsepower equation. The equation tells us that if you make the same amount of torque at a higher engine speed, you will make more horsepower. For most engines, in order to make more peak power, a longer duration cam will push the peak torque point higher in the rpm curve. Combine that longer duration with larger intake and exhaust port cylinder heads, a short runner length intake manifold, and large tube headers and you have the makings of an engine that can deliver serious horsepower. But all these components also contribute to shifting the engine’s power band to a higher engine speed. A common power band spread will be 1,500 to 1,700 rpm. In some exceptional cases, this can expand to as much as 2,000 rpm, but that’s rare. In the quest for more normally aspirated power, longer cam duration and bigger heads generally narrow the power band to 1,000 rpm and the longer duration pushes the horsepower peak to much a higher engine speeds. In order to take advantage of the higher rpm power, this most often is solved by adding a deeper (numerically higher) rear end gear.

Street-driven cars usually don’t have the luxury of running a 4.56:1 or 4.88:1 gear ratio. Narrowing the power band also places greater attention on maintaining the engine speed within this limited area. This is where additional gears in the transmission really help. So in the case of a Competition Eliminator car powered by a high horsepower engine with a narrow power band, this could call for a five-speed manual transmission instead of a four speed. The additional gear reduces the rpm drop between gears which will maintain the engine within its power band with the result being the car is now a tenth or perhaps two-tenths quicker. Even the OE’s have picked up on this effect. Note that as engines become smaller, with higher specific output, they generate less torque. To make up for this lack of torque, the OE’s have been adding more and more gear ratios to their transmissions. Chrysler, for example, currently has an eight-speed automatic transmission. The reasoning behind this increase in ratios is to maintain the rpm within a given rpm range where the engine makes power.

The difficulty with street-driven cars is that they are often compromised by the demand for more street-oriented rear gear ratios and limited to three- or four-speed automatic transmissions. An overdrive transmission can help by allowing the use of a deeper rear gear to help acceleration, but the overall limitations still apply. This brings us back to the question that every performance enthusiast needs to investigate if he is interested in improving acceleration. We’ll use the drag strip as our evaluation criterion for power improvements and what you’ll discover might change the way you think about adding power and where you should place your efforts so that it will do the most good.

Let’s use an example to illustrate the point. We put a 355ci small-block Chevy on the dyno and compared the power produced by a single plane versus a dual plane intake manifold. We equipped our engine with a classic combination of a set of Edelbrock aluminum heads combined with a mild COMP Cams hydraulic flat tappet 268 Xtreme Energy camshaft with 224/230 degrees of duration and 0.477/0.480-inch valve lift with a 110-degree lobe separation angle. Along with a set of headers and a 750 cfm Holley carburetor, this engine could be considered the prototypical street small-block. The two intakes we tested were the Edelbrock Performer RPM dual plane compared against the Edelbrock Victor, Jr single plane.

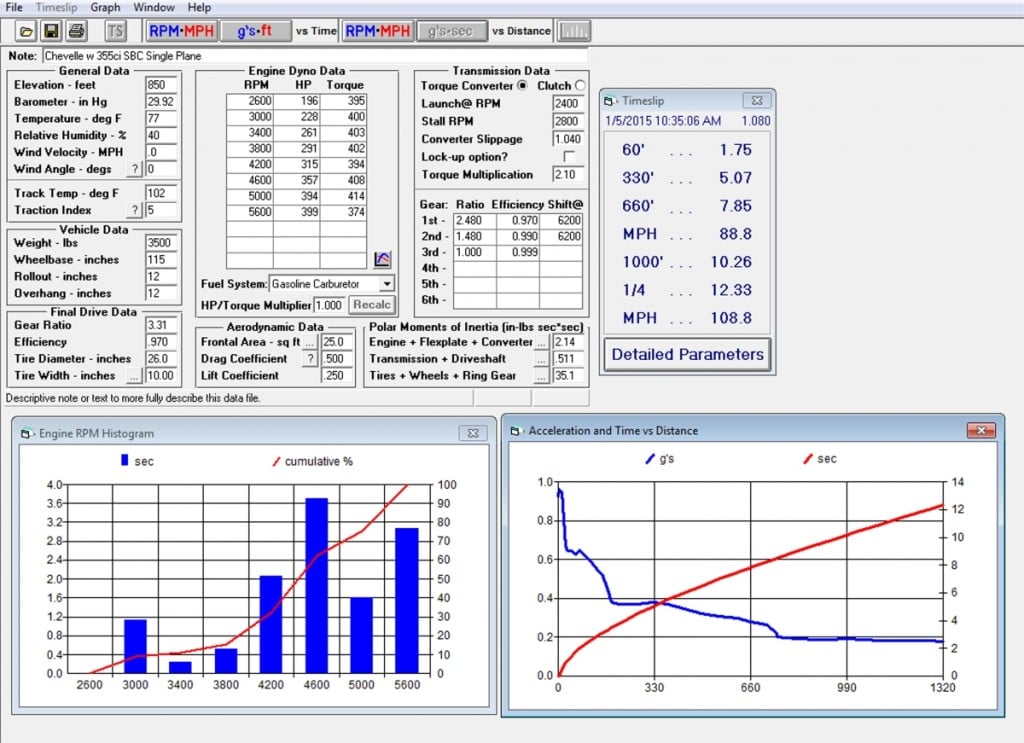

Besides the usual e.t. and speed results, the Quarter, Pro program also includes an interesting option called an RPM histogram. This chart reveals the amount of time the engine spends at various rpm points. This chart reveals very valuable information. For example, according to this graph this engine spends much of its time between 4,600 and 5,600 rpm. Armed with that information, it would seem like a good idea to concentrate on improvements in that rpm area because the power will deliver the greatest benefit.

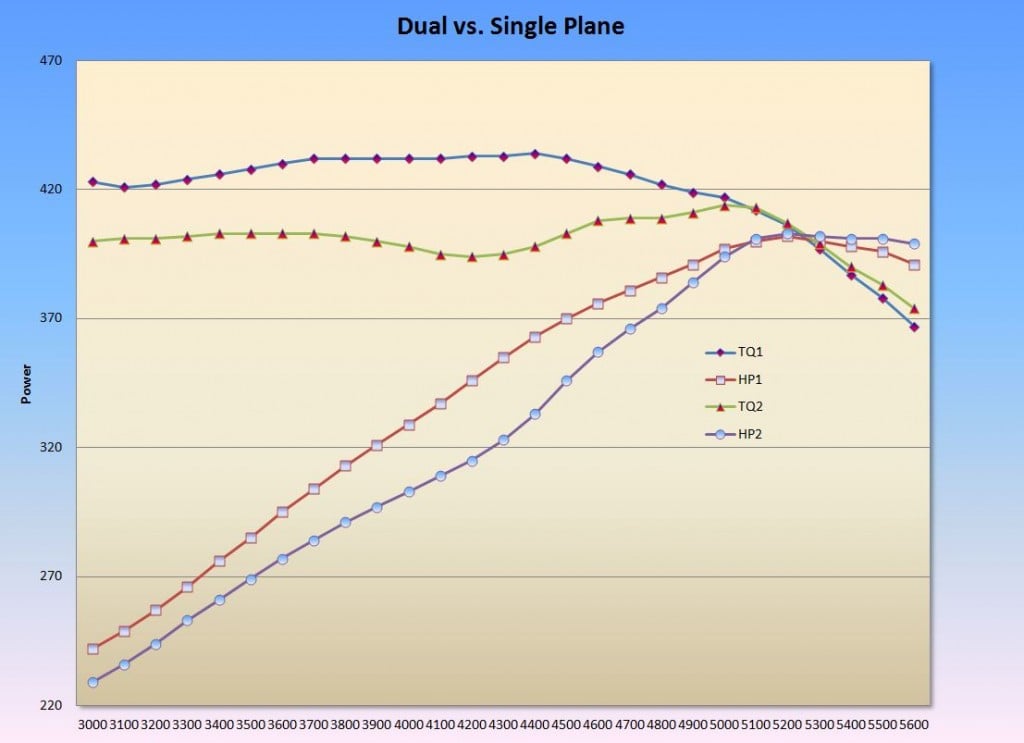

We ran both intake manifolds across this engine and recorded the torque and horsepower curves. Many engine guys will naturally look at the horsepower peaks and quickly make a judgment based on the higher horsepower number. In this case, the Victor, Jr. intake was worth 401 peak horsepower versus 398 for the dual plane. But when we plot both torque and horsepower curves on a graph, it becomes obvious very quickly that while the Victor, Jr. did out-horsepower the Performer RPM, the dual plane was clearly better at making torque – especially between 3,000 and 4,900 rpm. In this range, the dual plane made as much as 39 lb-ft of torque more than the single plane intake. That’s a huge gain in torque and something you would certainly feel in the seat of your pants when the throttle is planted firmly to the floor.

This graph and chart plot the power comparison of our small-block Chevy dual plane vs the single plane intake. Note the major torque improvements of the dual plane over the single plane below 5,000 rpm. For a mild street car, it’s clear that the dual plane is the better choice even though it loses as much as 22 hp to the single plane at the top.

We plugged these two power curves into the Quarter, Pro drag strip simulation program. This program was originally designed by Patrick Hale and it has become our favorite drag strip simulation program. Once we added the two different power curves into the program, it was easy to compare the differences in the projected acceleration rates. By now you’ve probably already figured out that the dual plane’s torque curve delivered much stronger acceleration. While the dual plane was worth as much as 39 lb-ft, the overall average was closer to 19 lb-ft of torque but that was enough to push our simulated Chevelle to run 0.15-second quicker and 1.4 mph faster. The numbers came out to a 12.33 at 108.80 for the single plane intake while the dual plane was quicker with a 12.18 at 110.20 mph.

The reason for the dual plane’s quicker elapsed time is its superior average torque. However, the reason for the quicker quarter-mile e.t. has as much to do with our test car as it does with the engine’s additional torque. This is an important point that is often lost when doing comparisons. In this case, we are using a relatively heavy 3,600- pound Chevelle with a three-speed automatic, a conservative 3.31:1 rear gear ratio, and a tight torque converter. If we were to plug these same comparisons into a lighter and smaller ’32 Ford coupe with a four-speed manual trans, deeper 4.10:1 gears, and big tires, the added torque from the dual plane would still be quicker, but the differential would not be as great. Let’s look at why this is.

We chose to make the ’32 Ford to weigh only 2,800 pounds, which will instantly improve acceleration but the real reason that the improvement wasn’t as great is because we changed the transmission. This has less to do with the type of transmission – converting from an automatic to a manual – and more to do with the reduced gear spread. By adding another gear (from three speeds to four), this reduced the rpm drop between gears, which narrows the engine’s operating rpm after it is launched. The Quarter simulation program gives us the rpm drops with each gear changed. Rather than go through all the numbers, let’s look at average rpm drop.

For the automatic, the average drop in rpm (using TH400 transmission ratios) was 2,140 rpm. Using a TR-6060 manual transmission (only the first four gears) this delivered an average rpm drop of only 1,630 rpm. The reduced rpm drop delivered by the manual trans keeps the average rpm 510 rpm higher at the completion of the shift. By nature, this will increase the average time spend at higher engine speeds. This tends to help the engine with more power at the higher engine speeds. But our simulation shows that leaving at around 3,000 rpm, the engine with the higher average torque in the middle still accelerates quicker.

As you can see with these examples, average torque is a much better way to evaluate an engine’s performance than just using peak horsepower. As we’ve mentioned earlier, these examples are all aimed at a typical street car – not a dedicated drag car. In the case of a dedicated drag car, the power band will tend to dictate the type of transmission used. So with a narrow power band, a manual trans with more gears is a good idea. In the case of a class legal car where a two-speed automatic transmission (like a Powerglide) is required by the rules, this would dictate building an engine with a wider power band in order to compensate for that huge rpm drop. Actually, from what we hear, some Powerglide racers use a very loose converter to keep the engine speed high even after the shift.

To condense this down to its logical conclusion, if performance and acceleration are the primary goal, then the street car builder has essentially three approaches. The first is to build the drivetrain around the engine’s power curve to optimize performance. The second is to build the engine to take advantage of the car’s existing drivetrain. The third option is where most projects exist – they optimize the engine as best as possible within the limitations of the current drivetrain. From this starting point, the builder can begin to approach the way the car needs to be constructed. If your plans call for a heavy car with an automatic transmission and a relatively tight torque converter, the ideal engine would be a large displacement engine or a possibly a small-block with a positive displacement supercharger than will make lots of low-speed torque. Or, if you really want to build a high-winding, small displacement engine that will spin to 7,500 rpm, an engine like that would be best served in a lightweight body style or perhaps a street rod equipped with a manual transmission – preferably with a deep rear gear ratio to keep the engine in the rpm range where it can make its power. Another example for that high rpm small-block might be open road race top speed car where you can choose a rear axle gear ratio and tire size that will put the peak horsepower rpm at or near the vehicle’s top speed potential.

Gear Ratios

The following is a comparison of the Chrysler 8-speed automatic versus the old school three-speed 727 Torqueflite. We list the ratios as well as the percentage of rpm drop between shifts. As the number of ratios increase, the rpm drop between gears decreases, maintaining the engine speed within a narrower power band. The additional gears also allow a much deeper First gear as evidenced by the 4.71:1 First gear in the eight-speed. Also note how Third gear in the eight-speed is nearly the same ratio as First gear in the 727.

The opposite effect is what many drag cars with very high torque and horsepower engines are using. For example, the Rossler TH-210 refers to a 2.10:1 First gear ratio in a TH-400 transmission that reduces the amount of torque multiplication over the tires. With a 2,500 horsepower engine, you don’t want to multiply the torque yet you still need a decent gear ratio to help launch the car. Second gear is around 1.30:1 which splits the difference between First and Third gear. This is still better than using a Powerglide with its large rpm drop between First and High gears.

Conclusion

None of the material presented here is shockingly new. But sometimes the proper approach can get lost in a world of hype and hyperbole. Building an engine with lots of peak horsepower will always be something to use as a goal, just don’t forget about the torque that gets you there in the first place.

Class legal cars like the SAM Racing 2012 (updated to 2014 body specs) runs a CC/Stock Automatic class legal LS7-based 427 with an A-1 TH3350 trans and converter. The Camaro, driven by Brian Massingill, has run a best of 9.14 at 145 mph and it gets there on a very strong torque curve combined with excellent peak horsepower – none of which the SAM folks are willing to divulge!