Aeromotive’s Phantom systems are designed to take all the fabrication and hassle out of installing a high quality fuel system featuring an in-tank fuel pump into your car–no matter what it is.

The advancements in technology that make possible today’s self-learning electronic fuel injection systems for hot rodders are fantastic. Several manufacturers are on board with systems that bolt right up, can handle tons of power and eliminate the old torture of spending untold hours with a laptop plugged into the car just so you can fiddle with confusing fuel maps.

But one of the first issues many hot rodders run into when they try to upgrade their carburetor to one of the new EFI systems is their fuel system must be reworked in order to handle the demands of electronic fuel injection. EFI requires a much higher fuel pressure than a typical mechanical fuel pump can provide. Even many electric fuel pumps designed for use on a carbureted engine cannot provide enough pressure to keep and EFI system happy.

But upgrading the fuel system opens up an all new can of worms. Because it has a low vapor pressure, gasoline should always be pushed and not pulled by creating a vacuum with the pump. Any time you place the electric fuel pump above the fuel tank, you have to pull fuel by creating negative pressure in the pickup and fuel lines. That negative pressure can cause the fuel to flash to vapor, which creates cavitation at the fuel pump and a poorly running engine.

The basis for all of the Phantom systems is (at least) one of Aeromotive’s super-efficient fuel pumps.

Typically, to fix this requires mounting the fuel pump so it is lower than the fuel tank. This creates all sorts of issues because the fuel tank is already pretty low. Now you are dealing with plumbing and a fuel pump that is exposed very low on the car, difficult to work around for the suspension and exhaust, and if it is visible, cluttering up the clean look of your great car.

The solution is to place the fuel pump in the tank–which is what the OEM manufacturers have been doing for decades now, anyway. Fuel pumps inside fuel tanks can be set up so that they are always pushing fuel to eliminate the issue of flash vaporization, and it also provides the pump a layer of protection from the elements, hides it from view, muffles the sound of operation, and keeps the electric motor cool so it will last longer.

And that is the idea behind all the engineering that has gone into Aeromotive’s Phantom fuel pump systems. Previously, lots of hot rodders avoided putting an aftermarket fuel pump into a stock fuel tank because it could be pretty tricky and require a lot of fabrication. And let’s face it, welding on a tank that has already had gasoline in it is not something many of us are comfortable with. But the Phantom systems fix all that.

“The Phantom series is the byproduct of years of frustration trying to help people get their fuel systems right,” explains Aeromotive’s Brett Clow. “I talk with car guys and racers every day, and I was hearing their frustrations from all these different issues they were having with their fuel systems. And I think our Phantom lineup of products can really help solve those problems.

“Aeromotive’s Stealth technology is anything we do when the fuel pump is in the tank,” he adds. “That includes our Stealth fuel cells and the new Phantom series. The Phantom is an installation technology that allows you to put that pump into practically any fuel tank. The point of the Phantom is to give people the technology that they need to easily — and I mean very easily — set up their fuel system to be able to handle just about anything. The tool requirements are a set of quarter-drive sockets, a hacksaw, a bread knife, and a cordless drill. That’s it. You can literally cut the foam to the size you need it with a bread knife.”

Aeromotive’s new Phantom in-tank fuel systems are really quite innovative. For example, they require no welding. That may not seem like such a big deal until you realize that includes installing the system in a corrugated tank that may not have a flat area large enough for the sealing ring. That is not a problem with the Phantom, the method Aeromotive’s engineers have come up with to seal the fuel pump in the tank can actually account for variances in height.

“It really was a challenge trying to develop this system so that it can work with practically any fuel tank,” Clow explains. “Number one, you’ve got to suspend it or support it in the tank so it does not leak. Also, you have to have a way to get the electrical power — power and ground — to the pump inside the tank. And making an electrical bulkhead that will safely pass that power and ground through the tank wall that will be hearty and robust and seal and not potentially leak — that’s a technology that is not available to just anyone.

“So the key thing about the Phantom is when you install it you are given a proper high-current draw, positively sealing electrical bulkhead assembly. Also, we supply the outlet port and the return port as well as an auxiliary vent. So when the Phantom is installed into the tank, it includes all the other modifications that need to be made to the tank in terms of ports and the electrical bulkhead. You don’t have to worry about it because that is already engineered into the Phantom.”

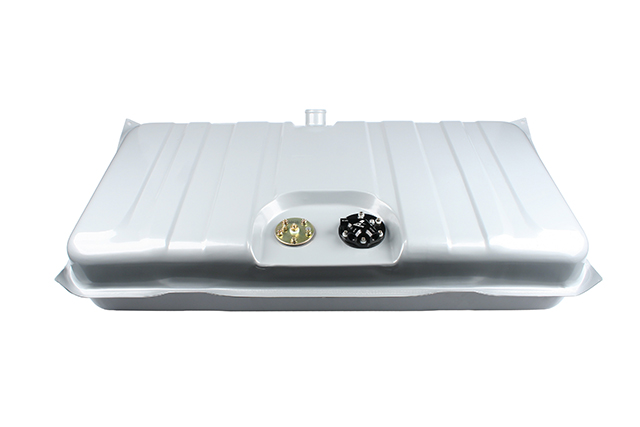

One of the cool things about the Phantom system is it doesn’t require a perfectly flat spot on your fuel tank for mounting. Notice where the access hole is being drilled across a corrugated portion of this tank. The Phantom collar can seal across the variances in height.

One of the most interesting facets of the Phantom in-tank system is how the baffle is designed to maintain a sufficient supply of fuel around the fuel-pump pickup. Especially with EFI, anytime the fuel pump isn’t able to provide a constant supply of fuel at the right pressure, it can cause a dramatic drop in performance. Aeromotive’s Phantom system is designed with lots of easy adjustability so that the height of the baffle, as well as the pickup for the fuel pump, can be placed near the tank’s floor no matter what tank you are using.

Aeromotive also put a lot of effort into properly sizing each baffle so that it holds a reservoir of fuel that is properly sized for the pump it is working with. In other words, the baffle for a Phantom 200 that can handle up to 750 horsepower is a different size than the baffle that ships on a dual Phantom which has two fuel pumps and can handle 2000 horsepower.

“The baffle is what is so incredible on this system,” Clow says. “I have thought for years about how we can design a baffle that can be installed into a tank so that it does not require the guy to have a welder. If you have to get out a welder, now you are talking about welding on this galvanized thin-gauge steel. So not just any guy who can weld can do this. And even if you are a fantastic welder, after you have welded on the tank, now you have burned away the coating and you’ve created an area where the steel can rust and corrode over time. It just isn’t a good situation.”

If you need a fuel tank, Aeromotive has a line of Stealth tanks that already incorporate an in-tank pump, the electrical bulkhead and even outlet, return and vent ports built in.

The bladder itself is fabricated from unique aerospace fabrics. It’s more than a simple rubber. We are told that it is completely compatible with gasoline, ethanol and methanol. In fact, there is no fuel currently on the market — other than nitro methane — that has any effect on this material. The same is true for the foam that is used to help the bladder hold its shape after it is inserted into the fuel tank.

“I have talked to some guys that were worried about the foam breaking down, because they have had a bad experience with the foam in a cheap fuel cell,” Clow says. “But be assured, this is not the same stuff.

Here’s another angle of the Phantom system. Notice how the electrical bulkhead is engineered into the system. It’s just one less task you have to worry about.

“These are very high-end materials that we are using for both the foam and the bladder, because we realize that once it goes into the tank it’s not going to come back out — and we don’t want it to come out. So we have done our research to ensure that it is a quality product, and it is a long-term solution for your fuel system.”

Everything about the Phantom system is designed around ease of installation and helping the fuel pump to do its job as well as possible. And the pumps, of course, are Aeromotive’s innovative high-flowing units.

“All these pumps are what we call turbine pumping mechanisms,” Clow says. “It is not a rolling vane, sliding vane or a geroter. In other words, it’s not a gear meshing type of mechanism. It is just a disk that’s highly machined with a turbine kind of cut.

“These types of pumps will not make any measurable type of vacuum. They are not positive-displacement type pumps. But because of the way they work they are whisper quiet. There is no meshing sound as the pumping system moves the fuel, it’s only a spinning disk. And because there are many very tiny cuts in the disk, it can be sped up and slowed down much more easily than a typical positive-displacement pumping mechanism. They don’t cog when you stop them and start them. And it’s amazing how much volume they can move.”

The Dual Phantom

The Dual Phantom places to independently functional fuel pumps in the tank to provide you a variety of options depending on your horsepower needs.

One of the more interesting products in Aeromotive’s Phantom lineup is their Dual Phantom in-tank unit. The Dual Phantom places two of Aeromotive’s 340 pumps (340 liters per hour at 40 psi) in the tank, and our immediate question was “Why use two pumps instead of just one BIG pump?”

It turns out there are two very cool reasons for running two fuel pumps in your tank. The first is for efficiency. With a little clever wiring, you can use a single pump to provide fuel for regular driving and not activate the second pump until you hit wide-open throttle when it is needed to provide additional fuel. This reduces the amount of unused fuel that gets pumped through the return lines and helps keep everything cooler. One way to do this is to run a vacuum switch to the intake manifold. Whenever the manifold sees vacuum, that means you are operating at part throttle and the switch stays off. But when you hit wide-open throttle the vacuum drops in the intake manifold, kicking the switch on and firing up the second fuel pump to ensure you have plenty of fuel at the injectors when you need it most.

The second reason can be pretty useful to long distance and endurance racers. Clow says many off-road racers have fallen in love with the Dual Phantom setup because it gives them a switchable backup pump that allows them to keep racing in the event of an issue without ever getting out of the truck.

The Dual Phantom isn’t just two pumps, it’s practically two of everything. “The off-road guys really appreciate being able to have redundant systems,” Clow explains. “With twin electrical systems on the Dual Phantom you have complete control of the pumps. You also have a separate fuel port outlet for each pump, so they can route one of our fuel filters for each pump and then go to a common line that runs to the engine. A pump failure is pretty rare, but a clogged fuel filter is more common in those conditions they are racing in, so if a filter clogs they can just switch to the other pump and just keep racing.”

Source

Aeromotive

aeromotiveinc.com