They don’t look revolutionary at first glance, but Comp Cams’ new conical valvesprings stand to be a real game changer when it comes to helping performance and race engines make more power.

When it comes to racing—and even making horsepower in general—paying attention to the details is the key to success. In fact, the great champions are infamous for sweating the details almost compulsively.

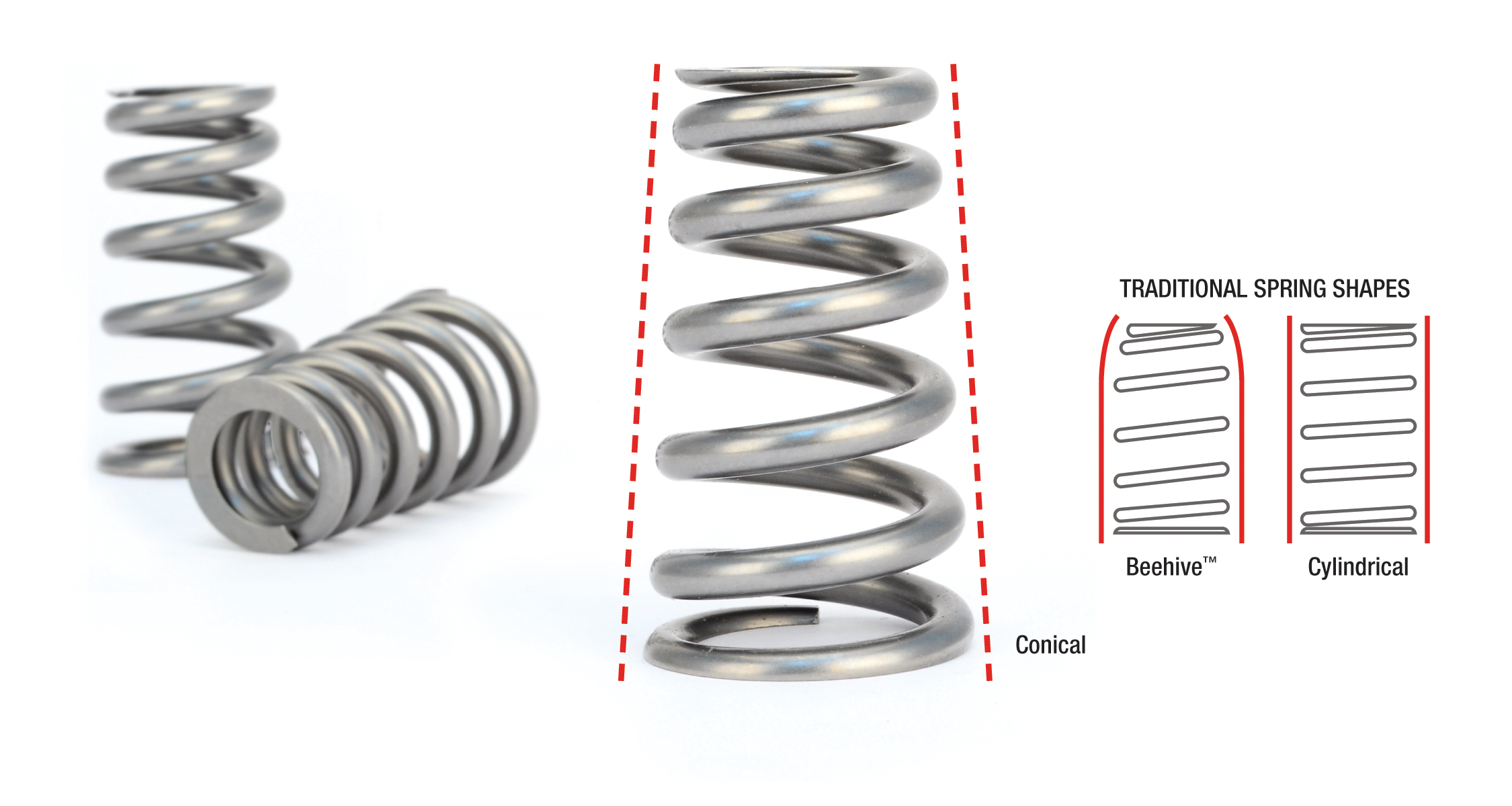

And the same thing holds true for engine builders and the manufacturers of the components they use. A perfect example are the new conical valvesprings made by Comp Cams. At first glance they don’t look like much—just a valvespring that’s narrower at the top than the bottom. In fact, it looks a whole lot like a Comp’s very successful beehive valvespring without that distinctive arc in the profile.

But there is very much more going on here than meets the eye, so much so that these new springs really look like they can be a game changer. The major difference is as simple as the geometry. Instead of a vertical column, as you move up the conical spring each coil gets slightly smaller in diameter so that it winds up looking like—you guessed it—a tiny cone.

It turns out the simple geometric cone shape as a few significant advantages when it comes to increasing the performance potential of the valvespring.

Cutting Weight

The higher up the valvespring you go, the farther that coil moves up and down every time the valve opens. So by stacking progressively smaller coils on top of each other, you significantly reduce the effective mass of the spring. Plus, the small top coil utilizes a smaller (and lighter) spring retainer.

When it comes to the valvetrain, weight is the enemy. Any time you can cut mass while maintaining the same spring pressure you can increase the rpm level at which the engine is able to maintain good valve control. Narrowing the diameter of the spring not only cuts weight from the spring itself, but it also allows you to use a smaller retainer which also helps to reduce mass in the valvetrain. The larger diameter coils at the base of the spring helps keep the spring pressure higher, but because the coils don’t move nearly as much as the coils at the top of the spring, the extra mass isn’t really harmful when it comes to maintaining valve control in the upper rpm ranges.

Reducing Harmonics

The narrower top has been done already with Comp’s innovative beehive valvesprings. The really big deal with these new conical springs is how the new shape actively dampens valvespring harmonics, which can be tremendously damaging to both the engine’s power and the lifespan of the springs.

With every other style of valve spring there is a rate, or an rpm level, where the speed that the engine opens and closes the valves matches the speed at which the coils essentially vibrate. When you hit this rpm range, the valve springs enter a harmonic stage where the vibrations travelling up and down the spring are in sync and grow in strength. When this happens the spring’s ability to maintain the proper movement of the valve is drastically reduced and the chances of breaking a valvespring are multiplied.

But the unique shape of the conical spring actually works to resist harmonic waves travelling up and down the spring.

The rpm level a spring will go into resonance depends on a few factors–namely the diameter of the spring’s coils, the diameter of spring wire and the metallurgy of the wire the spring is made from to name a few. But because no two coils on a conical spring are the same diameter, that means when one coil goes into a harmonic state the coils above and below it aren’t and can absorb the harmonic wave without allowing it to pass through and gain strength. This way the spring can never go into resonance or a damaging harmonic state.

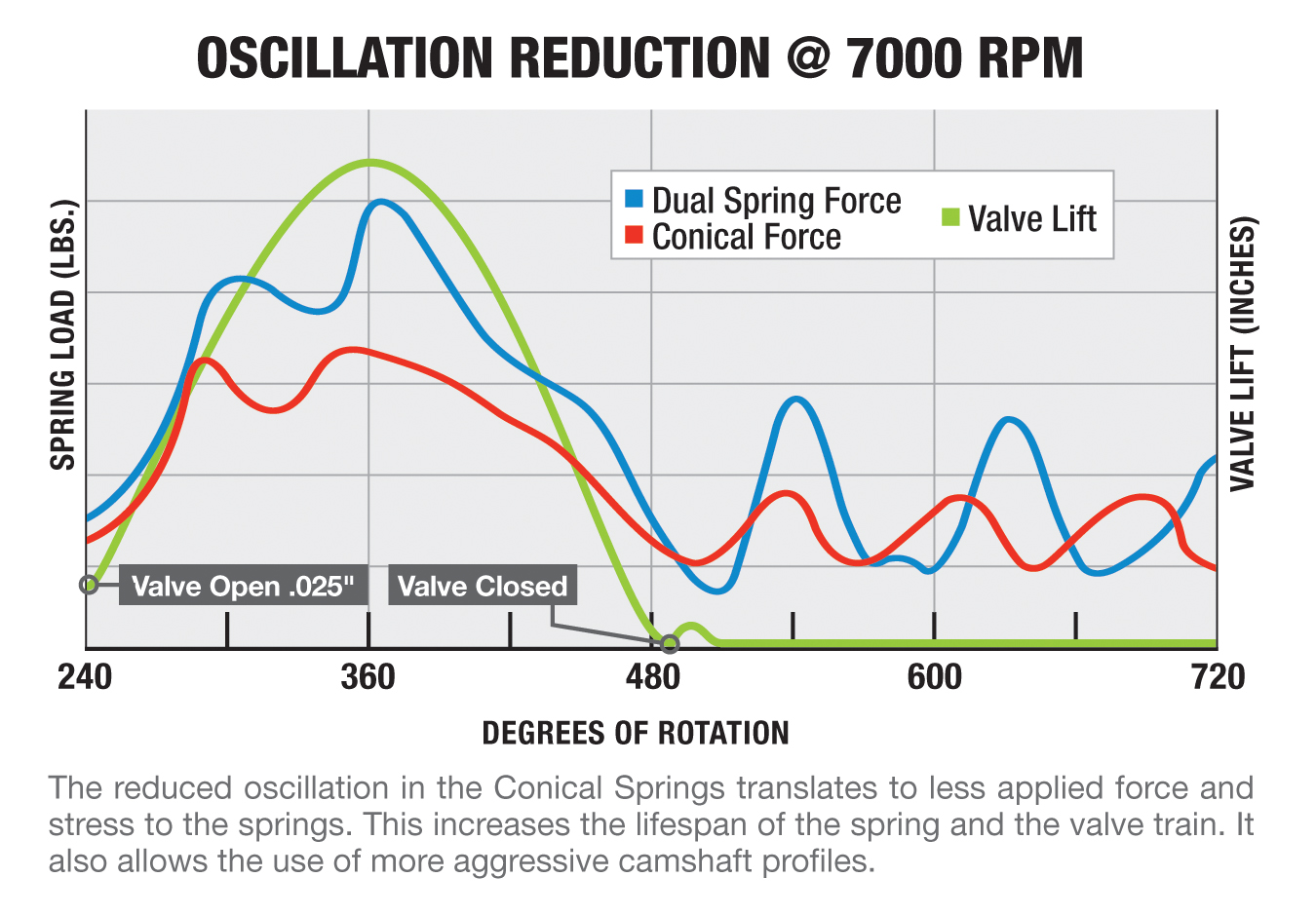

“What really shocked us when testing the conical design,” Comp’s Billy Godbold says, “is once we found the correct aspect ratio–the pitch from the bottom to the top of the spring–the damping between all the coils was so much better. If you put a load cell on any of these (conventional or beehive) springs, you see that they go through clash modes every couple hundred rpm. But with the conical springs we couldn’t find an rpm or a situation where they would go into the same clash mode.

“And that all comes down to the shape of the coils,” he continues. “That ratio that the coils decrease in radius from the bottom of the spring up to the top isn’t an accident. That’s a very specific ratio, and we control it by using very precise CNC spring coilers. But the result is it makes it where nowhere in that spring is it the same frequency a half coil–or even a quarter coil–further down. And that makes all the difference in getting rid of those harmonics. If you imagine each coil is like a band pass filter and each coil filters out a different frequency. So nothing passes all the way through so it can become a wave. Because anything that excites the bottom coil can’t excite the top. The harmonic waves just stop.”

Geometry Equals Horsepower?

These new conical valvesprings are very new, but we expect to see them start showing up in engine built by the top engine builders very soon. When they do will will follow up with more detailed reports on how they are actually working in the harsh world of competition.

Ok, so that’s a nice and all, but how exactly does that geometry lesson have to do with making power?

Godbold explains that when a spring goes into harmonic resonance, it acts like a very effective rev limiter and your expensive race engine just “hit the chip” so to speak. The loss of valve control that happens when the spring is in resonance means the valve is bouncing on the seat, and all that compression you’ve worked so hard to build is bleeding right out the exhaust pipes. The power loss is so severe that most engines aren’t able to push through that harmonic rpm range.

Testing has shown that by switching to a conical valvespring with equal, or sometimes even less, spring pressure an engine will often gain 200 or more rpm at the redline simply by getting rid of the power-robbing harmonics. Godbold says that high performance and race engines are often “over sprung” to help compensate for the loss of control that comes with valvespring harmonics. Because the conical spring doesn’t have to deal with that issue more of the spring pressure goes into controlling the valve just like you would expect. “We can push the spring and the engine much harder now because we know the spring can’t go into resonance,” Godbold explains.

The result that we’ve seen is simply by switching to a conical spring most race engines will gain rpm (which means you can switch to higher gearing) and power without any penalty in either longevity or bottom-end power. In fact, because the conical springs actively dampen harmonic waves Godbold says they usually live significantly longer than conventional springs without breaking.

This breakthrough design has the potential to be a real game-changer in racing, and we expect to see these innovative springs showing up on more and more race engines. And that will be the real test we can’t wait to report on–will these new springs help racers get to victory lane?

Resources

Comp Cams

(800) 999-0853