ARP’s Chris Brown was the final presenter of the 2015 edition of the Advanced Engineering Technology Conference, and the information was definitely worth the wait. You may think there isn’t much to know about threading in a bolt, but the fact of the matter is most engine failures we’ve seen haven’t been from defective parts or poor design, they’ve been because of some error made by the assembler. Here are some great tips to help you make sure your engine fasteners–and how you install them–won’t let you down.

Bolt Stretch and Clamp Load

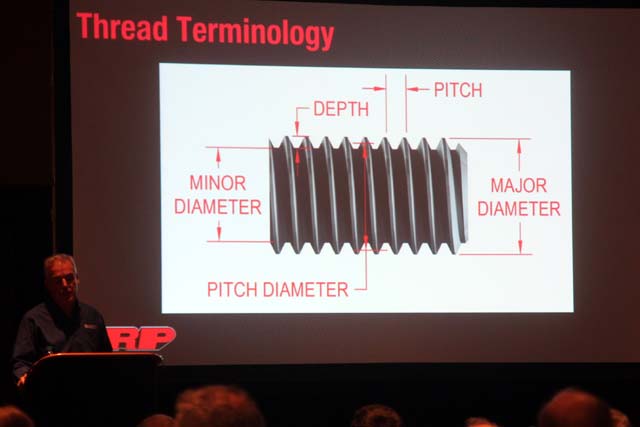

A bolt isn’t just a bolt. It actually has a complex anatomy and every part is critically important to its performance.

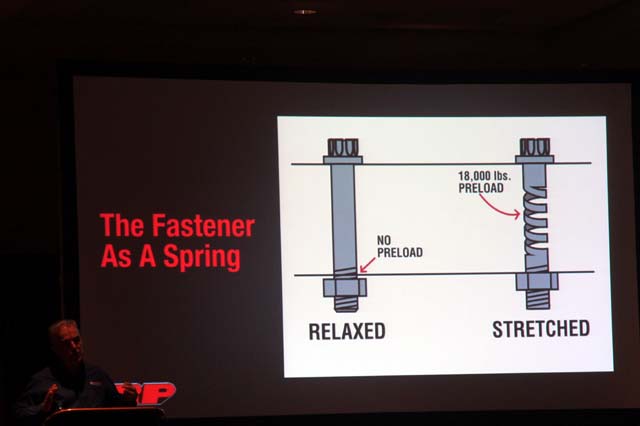

A bolt isn’t a static component in your engine. As you tighten the nut, the bolt actually stretches along its length. And because the metal is elastic, it is the bolt’s desire to pull back to its original length that actually provides the clamping load between the two components being held together.

A potential problem arises from the fact that a bolt’s elasticity is quite limited. If you over-stretch the bolt, it will go from “elastic” to “plastic,” meaning it has lost its ability to shrink back to size. When this happens the clamping load drops significantly and a bolt failure becomes likely.

Bolts can provide clamping force because they actually stretch, and the inherent elasticity of the metal wants to pull it back to its original length.

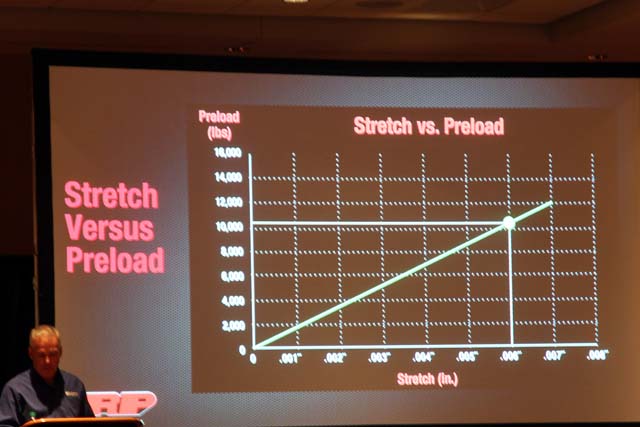

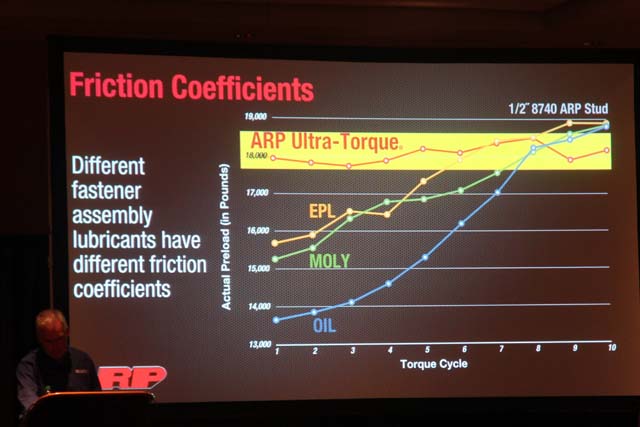

There are three main methods for determining the amount of bolt stretch. The first is torque, which is measuring the amount of force required to turn the bolt or nut onto the bolt. Torque can be affected by the friction between the threads, so if you have excessive friction between the threads you can reach the desired torque reading before the bolt is properly stretched. This is why using a quality thread lube is so critical when torqueing engine bolts. The second method is torque-plus-angle, which isn’t common in a racing environment. Torque plus angle tries to eliminate the variability that comes from measuring torque by torquing the bolt a lesser amount (where the chances for variation is less) and then turn it an additional number of degrees. Finally, you can simply measure bolt stretch. This is the most precise method because when you can directly measure stretch, you are eliminating any variables from torquing completely.

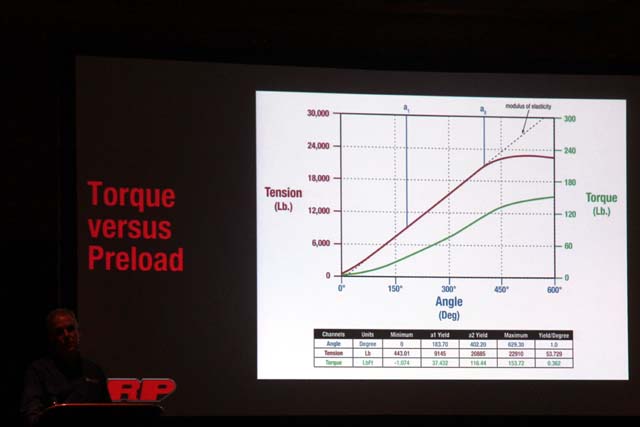

This graph compares clamping force as a fastener is stretched. Because the rate of increase is linear, it is easy to determine clamping load by measuring stretch.

Flywheel

A lot of people think that the flywheel bolts serve as sheer pins. They aren’t.

The flywheel bolts’ only purpose is to provide enough clamping load between the flywheel and the face of the crank to create enough friction to handle the torsional forces of the crank acting on the flywheel when the car is in gear. So you can see why it is critically important to get the correct amount of bolt stretch to maximize clamping load.

It isn’t a sin to use Loctite on your flywheel bolts, but you have to be aware that Loctite can change the torque value of your bolts. Install your flywheel bolts as soon as you apply the Loctite. If there is a delay (say, you answer your cell phone) between applying the Loctite and actually torquing the bolts, the Loctite can begin setting up and create more drag between the threads, causing your torque wrench to click before you’ve reached the ideal amount of bolt stretch.

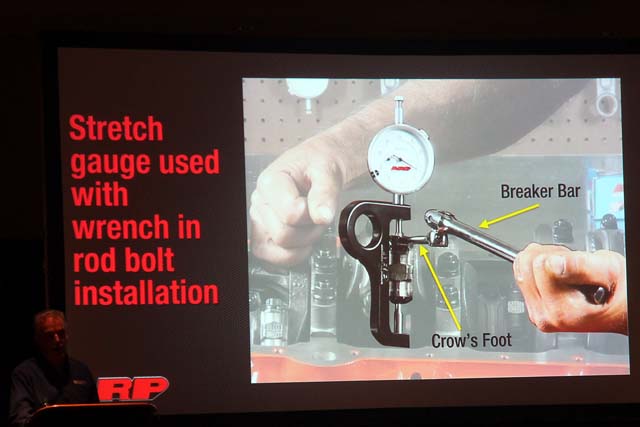

Here’s a setup so that the engine builder can measure connecting rod bolt stretch in real time instead of the usual method of torquing the bolt and then measuring stretch (which can be too late).

Once a bolt is over-stretched it loses its elasticity and goes plastic. That’s what is happening when the red line noses over. The bolt has lost its elasticity and is more likely to fail.

A quality lubricant is critical to achieving consistent torque figures. One problem even when using lubricant is the every time the bolt it tightened the process actually polishes the threads. So each time the same amount of torque on the wrench can produce more bolt stretch. This is why ARP developed its Ultra Torque thread lubricant–it provides more consistent results time after time.